|

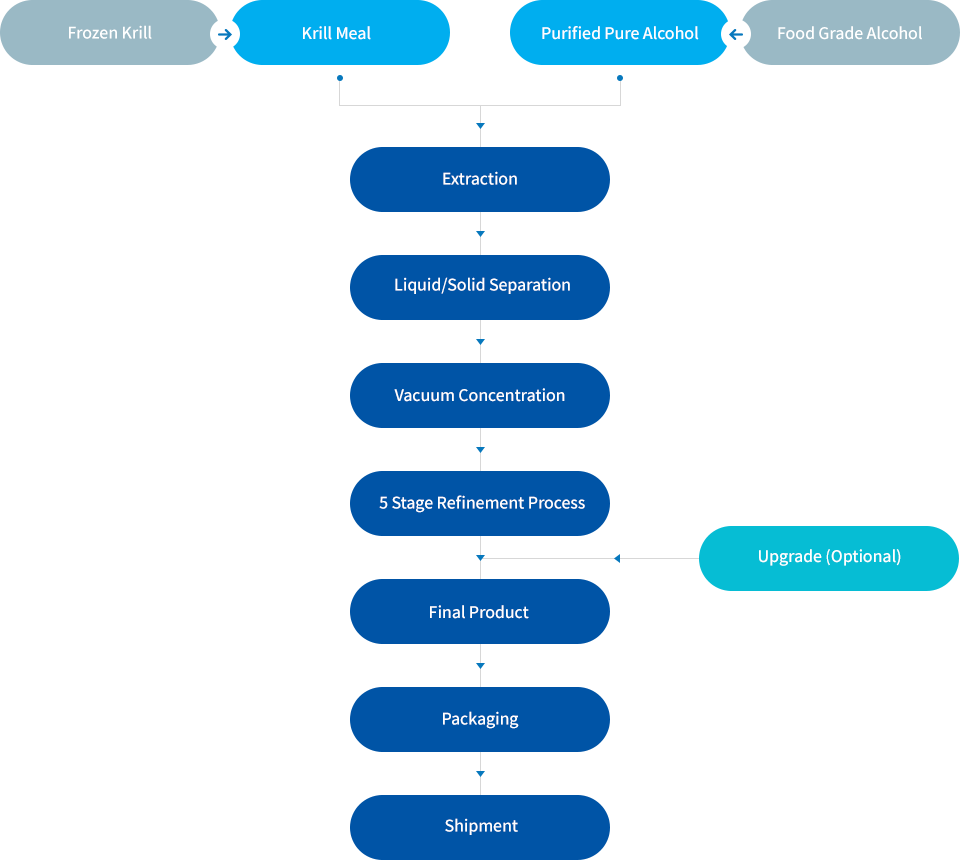

Preparation of krill meal

|

-

1-1 Purchase of frozen krill

We purchase frozen krill caught by Korean companies, and transport the krill in refrigerated containers.

-

1-2 Drying

We dry the frozen krill, and then process them to make krill meal. Biocorp’s processing technology that prevents from oxidation or reduction in active ingredient content is applied to the drying process. The produced krill meal has about 20% krill oil content.

|

|

|

Preparation of the solvent

|

-

1-1 Purchase of edible alcohol

We purchase edible alcohol with a permit issued by the Korean government.

-

1-2 Refinement of the solvent

In this process, any impurities that may exist in the edible alcohol are removed. Through this process, we make the safest extraction solvent in the world.

|

|

|

Extraction of krill oil

|

-

The krill meal and edible alcohol and mixed in an extraction tank to extract krill oil from the krill meal.

|

|

|

Separation of liquid and solid matters

|

-

Krill meal residues are removed using a centrifuge and filters.

|

|

|

Concentration

|

-

Alcohol mixed with the krill oil is removed by vacuum evaporation. Since the main ingredient of krill oil is sensitive to heat, temperature inside the evaporator is kept low. In general, temperature inside the concentrator is kept between 18 and 40 degrees.

|

|

The 5-step

refinement process

|

-

Biocorp’s refinement technology is very unique and efficient. The 5-step refinement process removes salt, proteins and odor from the oil. Biocorp does not use any non-edible substance in the refinement process.

|

|

|

An upgrade to high-purity krill oil (option)

|

-

Biocorp possesses the technology that can dramatically increase the content level of active substances such as EPA, DHA, and phospholipids according to the needs of customers who want high-purity products. Biocorp offers products with phospholipids content over 40%, over 50%, over 56%, and over 60%. Biocorp is the only manufacturer in the world that produces krill oil with over 60% phospholipids content.

|

|

|

Packing

|

-

The finished krill oil product is packaged in 200kg or 20kg HDPE drums that are filled with nitrogen.

|

|

|

Loading

|

-

The finished products are packed and transported in palettes. The smallest unit of sale is 200kg.

|

|